Precision Grinding Services

For nearly 60 years at Day Tool & Mfg, we have been a leading provider of precision machine parts, tooling, stamping dies, and special machines.

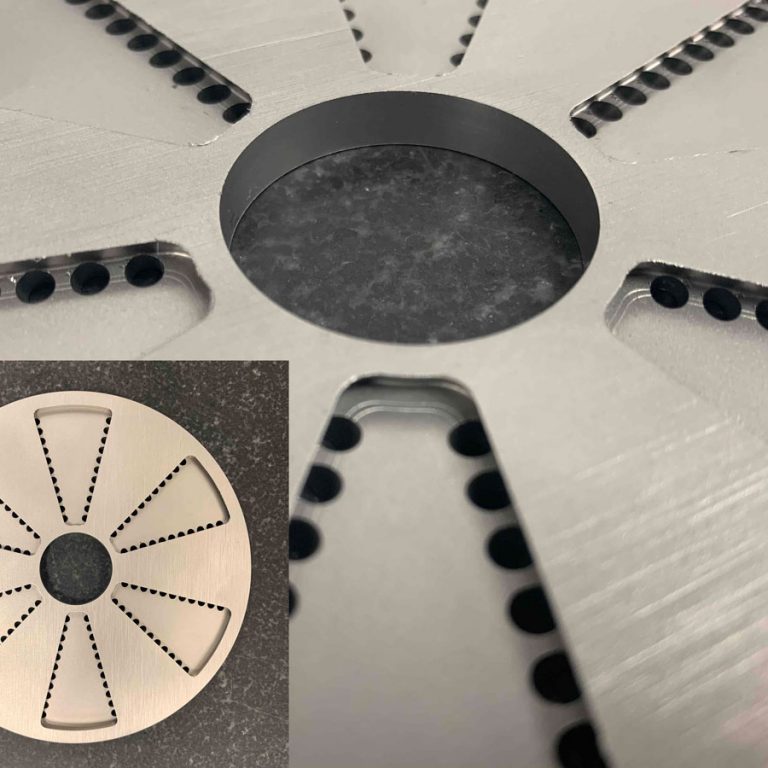

Our grinding and conventional machining services are executed by highly experienced machinists with many years of industry experience. These precision services utilize equipment that can perform jig grinding and boring, vertical milling, drilling, honing, and electrical discharge machining (EDM). These cutting edge capabilities allow us to work with a number of rubber and plastic materials, as well as a variety of metals from commercially available to exotics to heat resistant alloys. These precision systems can produce parts up to 39” in length and 20” in width with a high accuracy in parallelism, flatness, perpendicularity, squareness, and deliver mirror surface finishes.

Our dedication to customer service includes a welcome to tour our state-of-the-art facility —, 24,000 square feet, AS 9100, Rev. D and ISO 9001:2015 certified. We can handle any production run quantity from 1 to 1,000 pieces and can deliver in fast, making our services ideal for the aerospace, biotech, electronic, medical, pharmaceutical, and packaging industries.

To learn more about how our advanced surface grinding and conventional machining can help with your next precision manufacturing project, contact us or see the table below.

Precision Grinding Capabilities

| Grinding Processes | Surface Grinding Wet Grinding |

| Conventional Machining | Drilling EDM Honing Jig Boring Jig Grinding Vertical Milling |

| Process | Manual |

| Materials | Steel Stainless Aluminum Brass Copper Titanium Inconel Hastelloy Precious Metals Plastics Rubber |

| Part Length | Up to 39 in |

| Part Width | Up to 20 in |

| Surface Finish | Mirror |

| Inspection | Coordinate Measuring Machine (CMM) Optical Comparator |

| Additional Capabilities | Assembly Class 10,000 Clean Room Packaging Production Rapid Prototype Sawing Welding |

| Production Volume | 1 to 1,000 pieces |

| Typical Lead Time | 4 to 5 weeks |

Additional Information

| Industry Focus | Aerospace Biotech Medical Pharmaceutical Packaging Electronics Semiconductor |

| Intended Application | Precision Tooling Stamping Dies Special Machines Machined Parts |

| Industry Standards | AS 9100, Rev. D Certified (Aerospace Industry Standard) ISO 9001:2015 Certified (International Standards Organization) |

| File Formats | SolidWorks Autodesk AutoCAD GibbsCam DP Technology Esprit PC-DMIS CAD |